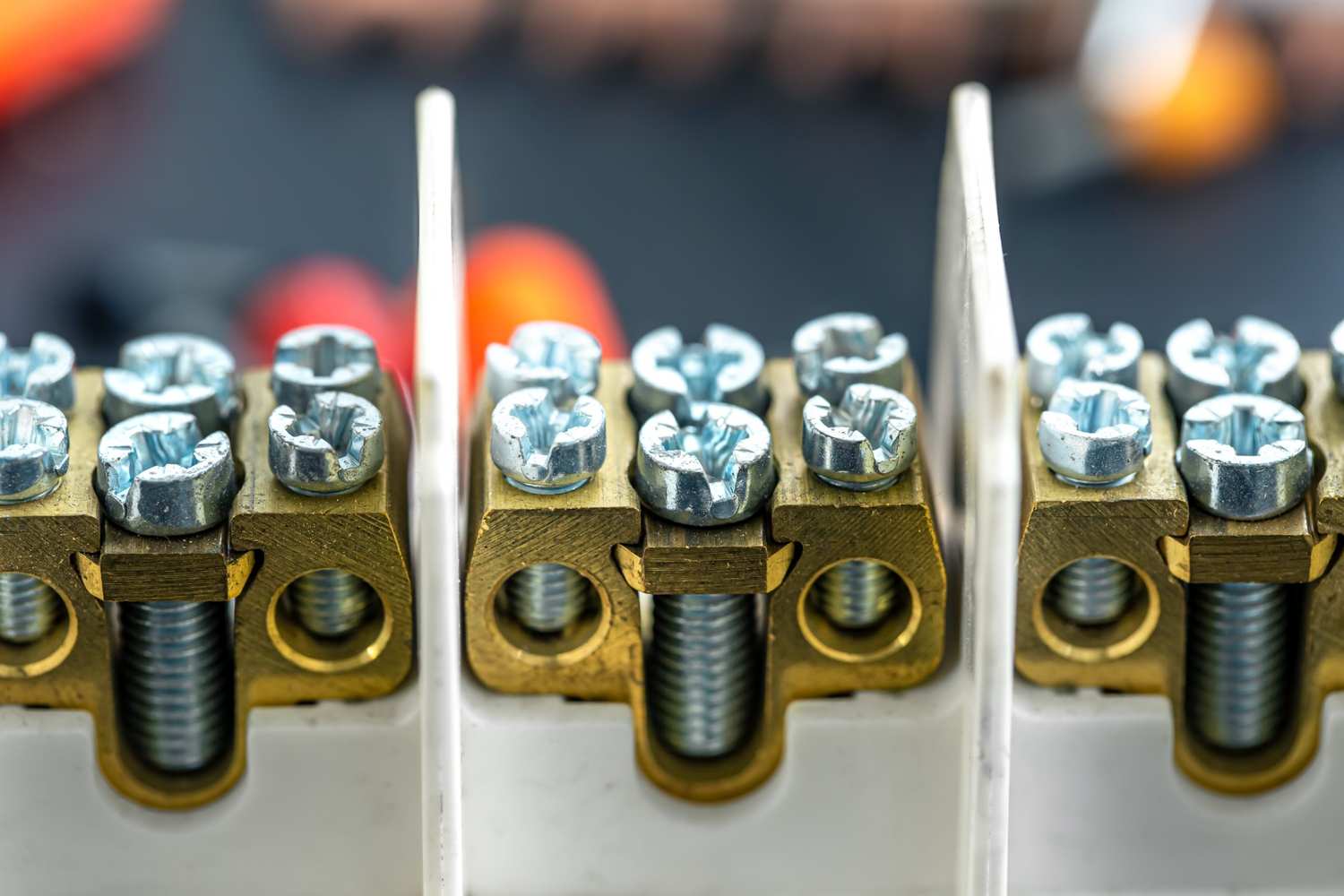

Industrial fasteners are the backbone of every structure and machine, from high-rise buildings to manufacturing plants. These small components, bolts, nuts, washers, and screws—hold massive systems together and ensure safety and performance under pressure.

However, when exposed to corrosion, vibration, or poor installation, even the strongest fasteners can fail. To ensure durability and reliability, a complete maintenance program that includes proper selection, installation, and ongoing care is essential.

When managed correctly, industrial fasteners can deliver long service life, reduce operational costs, and maintain mechanical integrity.

Selecting the appropriate material is the foundation of fastener longevity. Always consider environmental and operational conditions before choosing.

Choosing the right material reduces fatigue, prevents early wear, and enhances reliability.

Protective coatings create a shield against chemicals, moisture, and environmental exposure. Popular options include:

Applying these coatings helps fasteners maintain structural integrity over years of use.

Proper installation ensures that fasteners perform safely under load. Over-tightening may cause thread damage or breakage, while under-tightening can lead to loosening.

Precision torque application prevents slippage, vibration issues, and early mechanical failure.

Clean, dry threads are crucial for achieving accurate torque. Remove dust, oil, or debris before tightening. Apply an anti-seize lubricant when working with stainless steel or aluminum to prevent galling. Proper thread preparation ensures uniform pressure and easier removal during future maintenance.

Fasteners in vibrating or rotating machinery often lose clamping force over time. Use the following to prevent loosening:

These solutions maintain tension and extend service intervals for critical equipment.

Once installed, fasteners require consistent monitoring to ensure performance and safety. Preventive maintenance significantly reduces downtime and replacement costs.

Frequency depends on environment and application type:

During inspections, check for rust, cracks, deformation, or missing parts. Replace compromised fasteners immediately.

Temperature fluctuations and vibration can loosen fasteners over time. Regularly verify and re-torque connections according to the manufacturer’s specifications to maintain stability.

Keep fasteners clean to prevent buildup of dirt, grease, and contaminants that accelerate corrosion. Use mild cleaning solutions and soft brushes. Avoid abrasive chemicals or tools that can damage coatings. Always dry thoroughly before reassembly.

Lubrication minimizes friction, prevents galling, and improves torque accuracy.

Lubricated fasteners operate smoothly and resist rust longer, even in humid environments.

Storage plays an important role in maintaining fastener quality before use.

Proper storage ensures fasteners remain ready for use without degradation.

Even well-maintained fasteners have a service limit. Timely replacement prevents system failure and maintains safety standards.

Replace any fastener showing signs of:

Damaged fasteners compromise load capacity and increase the risk of failure.

Most manufacturers recommend reusing fasteners no more than two or three times. Torque-to-yield or single-use fasteners should never be reused, as they lose their holding strength after initial tightening.

Document fastener specifications, installation dates, and inspection intervals. Keeping detailed maintenance records allows for predictive maintenance, improved inventory management, and compliance with quality standards.

Recent insights from leading manufacturers emphasize that consistent maintenance directly impacts fastener reliability and performance:

These best practices reinforce that proactive maintenance is more effective and economical than reactive repairs.

Hamza Fasteners shares expert guidance on maintaining industrial fasteners through proper selection, coating, torque, and inspection to ensure durability, safety, and long-term reliability

Choose the right material, apply protective coatings, tighten to correct torque, and inspect regularly to prevent corrosion or loosening.

Use stainless or coated fasteners, apply protective finishes like zinc or Dacromet, and keep them clean and dry during use and storage.

Inspect fasteners every 1–3 months in corrosive areas and at least once a year in normal conditions to detect damage or loosening early.

Critical fasteners should not be reused more than two to three times; always replace any showing corrosion, stretching, or thread wear.

Industrial fasteners may appear small, but they bear immense responsibility for holding structures, machines, and components together. Their reliability depends on careful material selection, correct installation, and consistent maintenance. By implementing regular inspections, applying proper coatings, ensuring correct torque, and maintaining thorough documentation, you can greatly enhance the lifespan and safety of your fasteners.

A well-structured maintenance plan minimizes downtime, ensures operational safety, and delivers lasting value. In the long run, attention to detail and proactive care are what keep industrial systems secure and efficient.

At Hamza Fasteners Building Materials Trading LLC, we specialize in providing high-performance, corrosion-resistant fasteners designed for every industrial application. Our products deliver strength, precision, and long-term reliability in even the toughest conditions.

Contact Hamza Fasteners today to explore our wide range of fastening solutions or request a custom quote. Build your projects with confidence, quality, and durability that lasts.